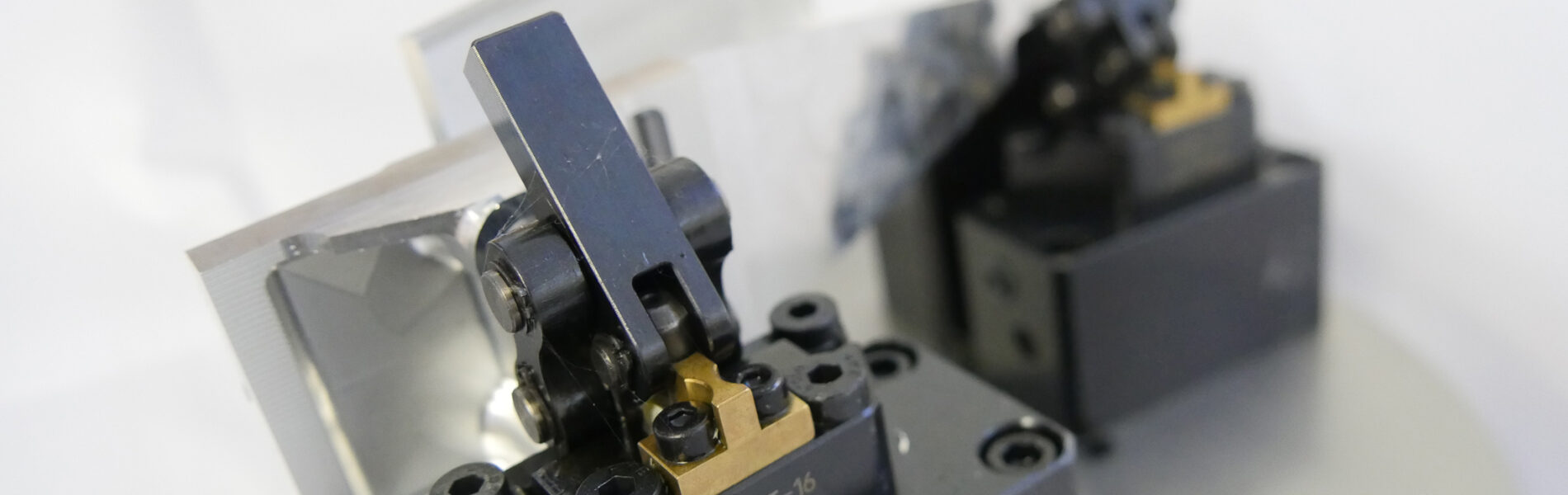

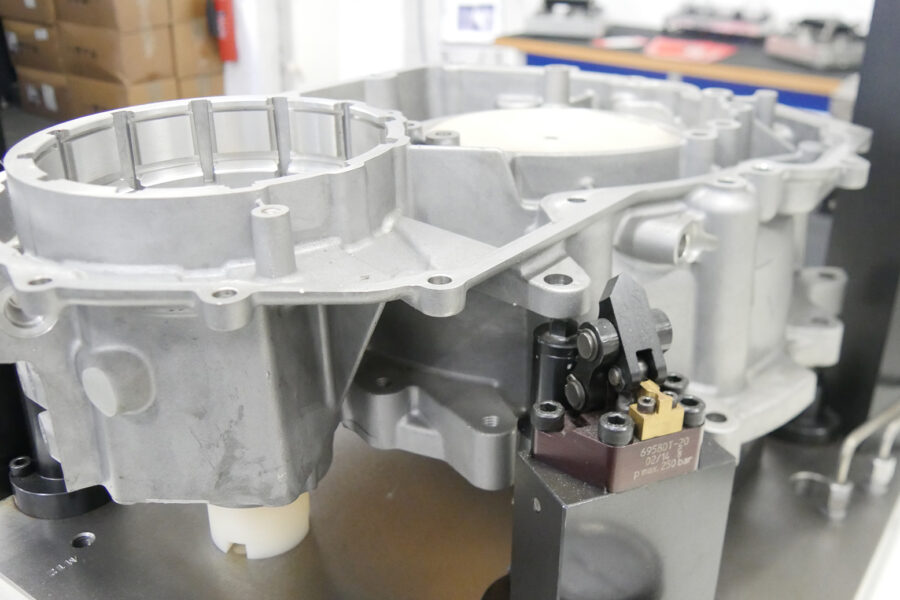

At Hyfore, we supply industry-leading CNC workholding clamps and CNC fixtures. Our bespoke manufacturing service supports manufacturers with a total solution to their workholding needs.

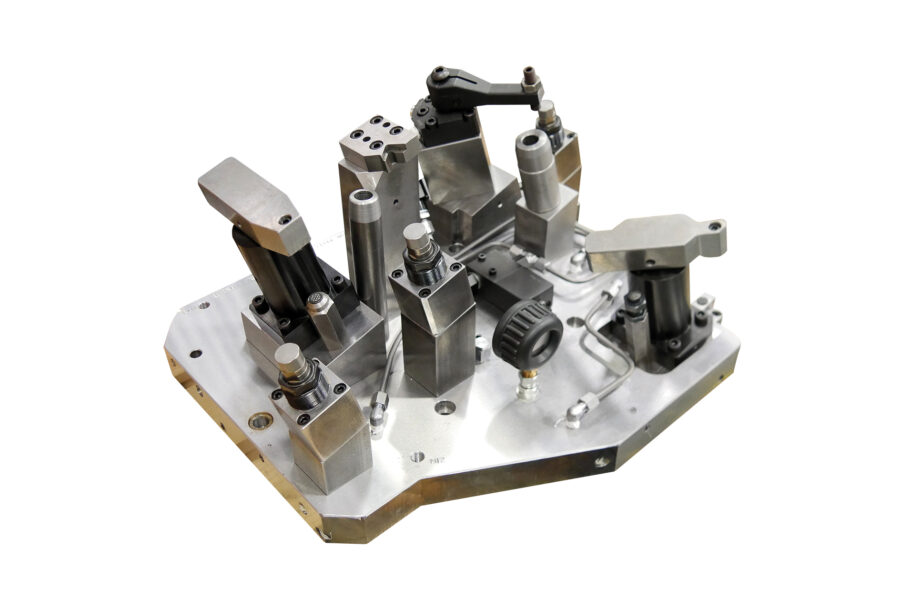

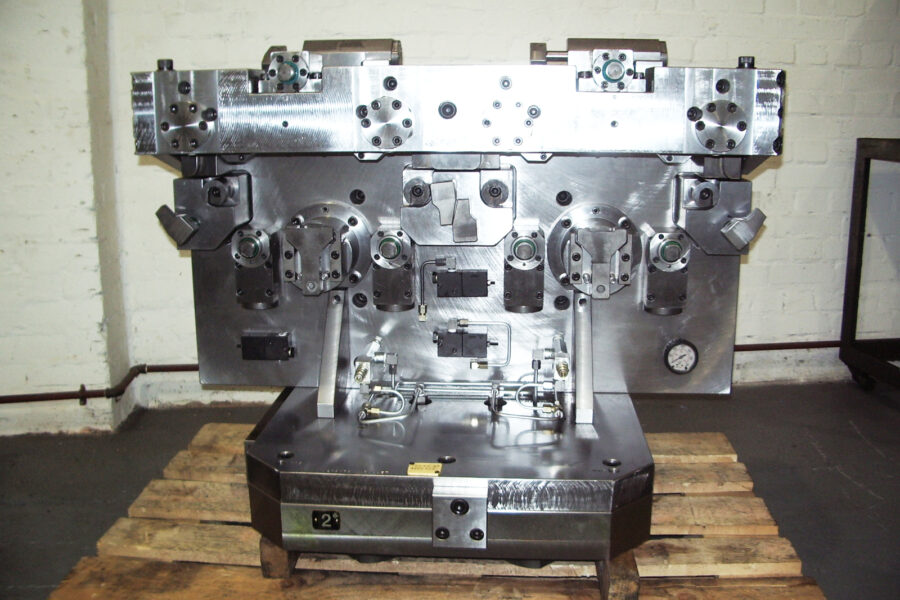

Based in Coventry, Hyfore’s in-house services range from design and manufacturing to project management and quality testing. We specialise in manufacturing complete, bespoke CNC workholding solutions, such as fixtures and clamps.

The result is a tailored fixturing system that will improve your productivity, precision and throughput. Our services are supported by Hyfore.shop. The Hyfore shop provides a vast range of standard workholding ranges from world leaders such as Kosmek and Midaco.

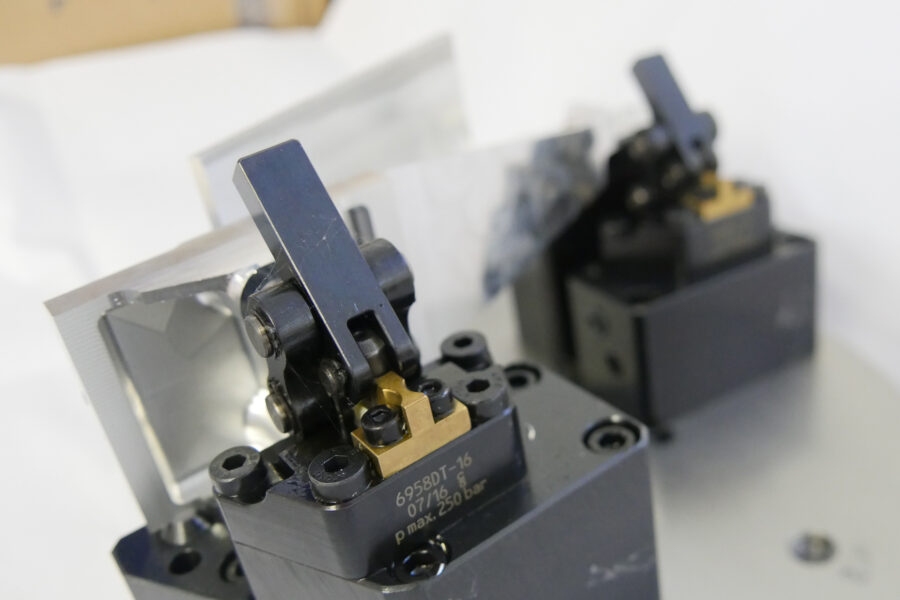

Hyfore’s experienced engineers and designers are determined to deliver complete, turnkey manufacturing for your CNC clamps and fixtures. So whether you require a hydraulic, pneumatic, automatic or manual clamping system, we can help. Get in touch to learn more.

Bespoke CNC Clamping Solutions

Our services also encompass mechanical and electronic design, using CAD/CAM 3D modelling. Our CAD/CAM capability gives us a clear advantage when viewing complex fixtures and tool cutter paths in relation to the fixture design.

Our bespoke clamping design and manufacture services are enhanced through the application of software from Mastercam, CAMplete and Cimco, with automation handled by specialist leading manufacturers – all combining to confirm Hyfore as the market leader for your full CNC workholding solution.

We have in-house quality, testing and prove-out facilities to ensure your project is delivered to agreed standards. Our quality inspection services are complemented by our complete project management, after-sales service support and even simultaneous engineering contracts.

Our Range of CNC Workholding Clamps & CNC Fixtures

1. Collets –

A key component of CNC turning, a collet works in tandem with the spindle. When machining, collet chucks provide a consistent gripping force, enabling you to safely operate the machine at higher RPMs and reducing your run-time. Benefits of collets also include:

- Fast set-up time

- Higher accuracy

- Custom collets are effective for off-centre CNC turning or holding odd-shaped parts

At Hyfore, we supply a wide range of ER, Autolock, R8 and 5C collets.

C-Style collets

C-style collets are cylindrical workholding devices used to clamp machine spindles for accurate, high-speed rotary machining. The spindle is inserted into the collet, and the collet is tightened using a nut, which squeezes the slits in the collet shut so it firmly grips the spindle. C-style collets are available in various sizes for a variety of applications.

Find out more

Collet blocks

We supply a wide range of Hardinge manufactured collet blocks, alongside a series of Hydraulic Accessories and Pneumatic Accessories, suitable for a variety of machining centres, applications and purposes.

Find out more

2. Self-centring machine vices –

Compact mechanical, pneumatic, hydraulic and electro-mechanical centre-clamping vices are available from Hyfore’s catalogue. We provide vices in a variety of sizes and assembly variations.

Discover our range of centre-clamping vices for both conventional and CNC machining.

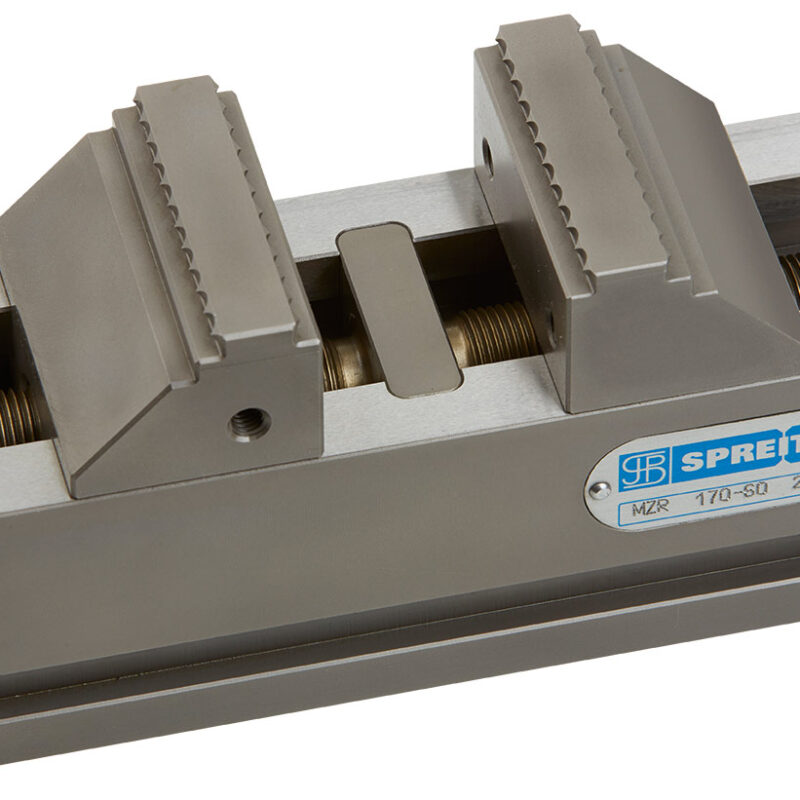

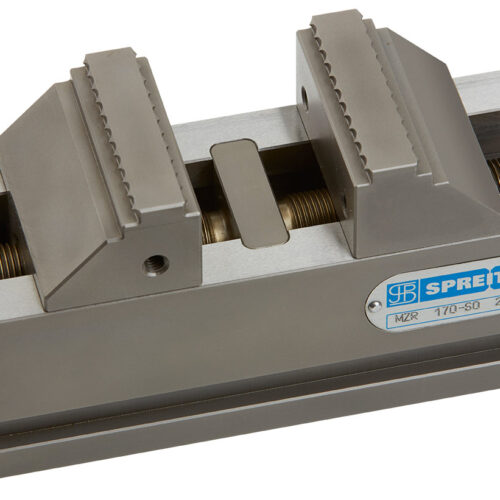

Spreitzer MZR

Mechanical centre-clamping vices that are used as a cost-effective solution for powerful raw material clamping. There is no need for pre-stamping and can be used on multi-axis machining centres and automation systems, with the rigid base body being optimised for 5-axis. These are best suited for use where maximum centering and repetition accuracy is not required. The units include one-piece reversible jaws with integrated grip steps, allowing for clamping range to be easily altered and providing maximum length.

Find out more

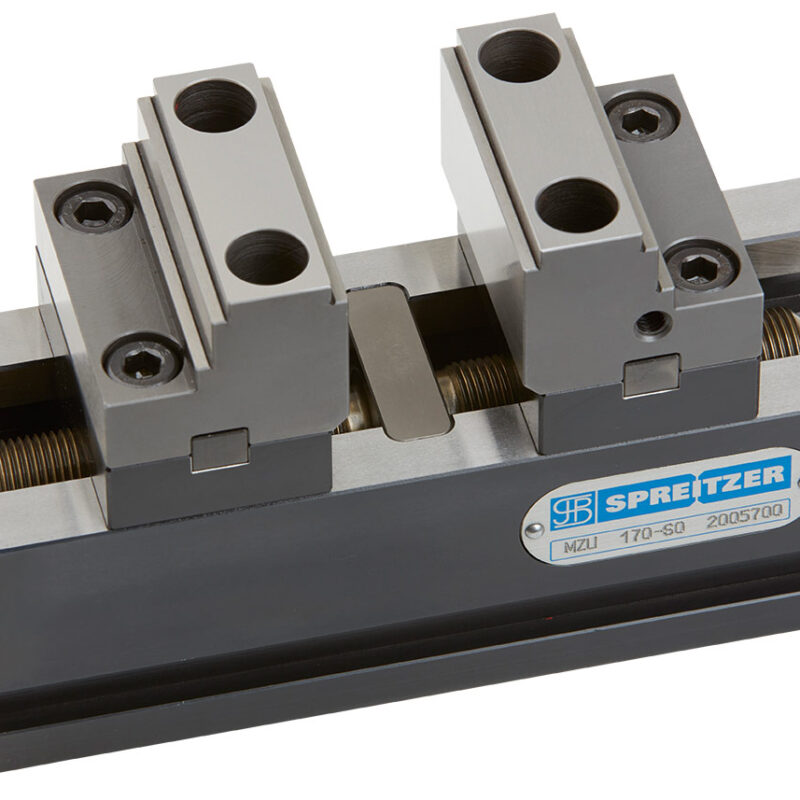

Spreitzer MZU

With the option of choosing reversible grip or soft block jaws, the MZU vice series allows the user a high level of flexibility and accessibility for multi-axis machining centres, even for short cutting tools. The reversible jaw distorts the surface of the workpiece, allowing for an increased holding force, with a protective coating applied to the product to eliminate the risk of premature wear and tear.

Find out more

Spreitzer MZE

With a compact design, wide clamping range and exchangeable jaws, this powerful centre-clamping vice series provides a flexible and economical workholding solution for your multi-axis machining centres and automation systems. Recommended for use on raw materials and pallet automation.

Find out more

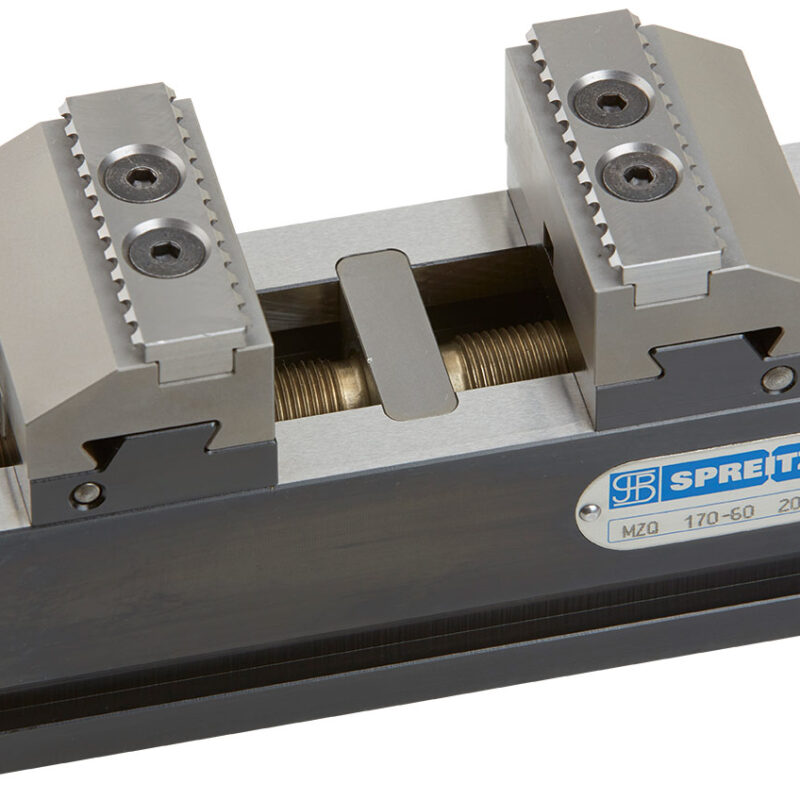

Spreitzer MZQ

The MZQ vices allow for the quick changing and replacement of jaws without the use of tools. They are designed specifically for use within pallet automation and have over 80% less setup costs than other vices. With reversible step jaws, these products allow maximum accessibility and have a large clamping range. Ideal for daily repeated retooling and has significant time savings when used on automation systems.

Find out more

3. CNC chucks –

4. Expanding mandrel –

Mandrels work by expanding within the bore of a workpiece, coming into contact with 95% of the holding surface and preventing distortion during the precision machining process.

The key features of our expanding mandrel include:

- Parallel gripping with maximum torque

- A built-in safety stop, eliminating the risk of over-expansion

- The ability to interchange collets

Our expanding mandrel

We provide a wide selection of Collet Style Expanding Mandrels, manufactured by industry leading partner Hardinge, offering solutions to difficult machining problems for turning, milling, grinding, assembly and automation applications. We guarantee exact workpiece lengths, even for particularly long parts, as our bespoke line of mandrels have extremely high stability.

Find out more

FAQs About our CNC Workholding Solutions –

- What types of CNC workholding solutions does Hyfore provide?

- What are the benefits of using Hyfore’s CNC workholding solutions?

- How does Hyfore maintain the quality of its workholding solutions?

- Does Hyfore provide ongoing support after the project is completed?

- What are the benefits of using Hyfore standard workholding collets in CNC turning?

- What are the benefits of using self-centring machine vices from Hyfore?

- How can I learn more about the CNC workholding clamps and fixtures offered by Hyfore?

Hyfore specialises in the in house design and manufacture of bespoke, hydraulic, pneumatic and manual CNC fixturing solutions, as well as offering an extensive range of standard workholding systesm. All this means we can help you find the right solution for your workholding needs.

Explore our complete range of workholding solutions here.

Our tailored fixturing systems enhance your productivity, precision, and throughput. Our experienced engineers and designers work diligently with you the customer to provide manufacturing solutions that meet your requirements.

Some of the key benefits of our workholding solutions include but are not limited to:

- Increased efficiency and lower costs: our workholding systems enable quick and repeatable setup, maximising productivity and reducing downtime.

- Versatility: our CNC clamps and fixture design can accommodate various workpiece sizes, materials and shapes

- Enhanced precision: our workholding solutions provide accurate, repetitive and secure workpiece positioning, ensuring precise machining.

At Hyfore, we have industry-leading quality inspection equipment that means each project is delivered to the highest standards.

Our experienced team conducts rigorous quality inspections to verify the precision and reliability of our fixturing solutions. Learn more about our CMM inspection services.

Absolutely.

We provide complete project management and after-sales service support.

We are committed to ensuring customer satisfaction throughout the entire process and are available to address any questions or concerns you may have, even after the project is completed.

Hyfore offers a wide range of collets, including ER, Autolock, R8, and 5C collets. These collets are essential for CNC turning and provide consistent gripping force, enabling safe operation at higher RPMs, faster setup time, and higher accuracy.

Collets deliver several benefits in CNC turning, including faster setup time, higher accuracy, and the ability to safely operate the machine at higher RPMs, reducing run time.

Custom collets can also effectively handle off-centre CNC turning or hold odd-shaped parts securely. Browse our wide range of collets today.

Our standard workholding vices come in various sizes and assembly variations, suitable for both conventional and CNC machining. Self-centring machine vices offer several advantages, including improved workpiece stability, precise positioning, and easy clamping.

By using these vices, you can enhance the accuracy and efficiency of your machining processes.

Contact us to learn more about our complete fixture design and manufacture service as well as our standard workholding systems. Our team will be happy to provide detailed information and assist you in finding the right solutions for your specific needs.

Get in touch to learn more about the rest of our CNC workholding clamps and fixtures.